Hydraulic Press Machine

Vertex has integrated and designed custom tooling and press frames for staking, crimping, swaging, pressing.

This expertise allows us to be very flexible in our designs and automation methods. Other applications that have been developed for automation processes include drilling, milling, boring, and debarring.

|

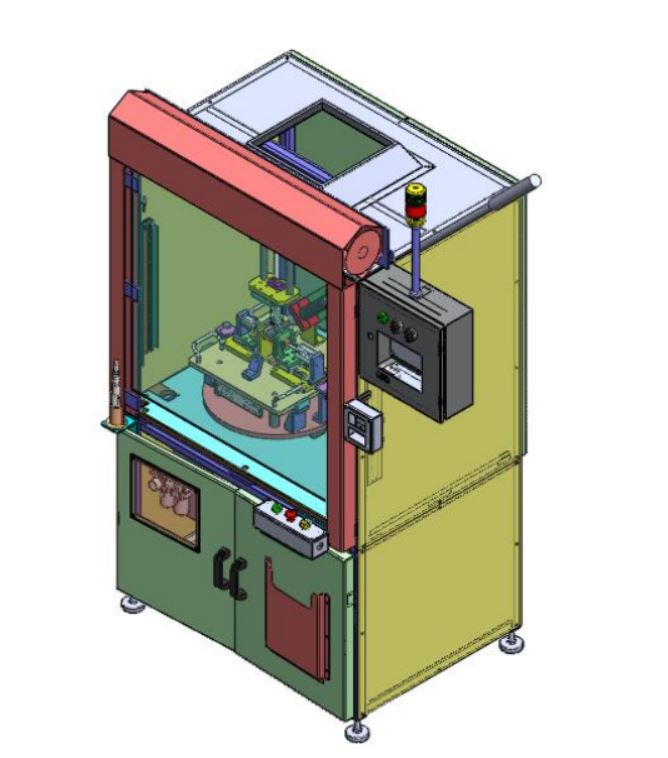

Window Regulator Machine

Window regulator is a device which regulates the car window up and down; there are various types of mechanisms. They are different in design and operation it can be operated manually as well as automatic. With efforts of hand, you can manually roll the car window up and down. Vertex provides Automatic window regulator system by simply pressing corresponding button to roll the window up or down. The electronics will do ever think by itself- the single directly transmitted to the reversing motor and then latter will begin to move on the rail. Depending upon the configuration of a car where switch button is located.

Project by Vertex Automation

Vertex has offered WINDOW REGULATOR LINE SPM (MODEL : Y1K) OF SHIROKI TECHNICO- BAWAL

|

Greasing & Dispensing Machine

Greasing dispensing machine is used for dispensing high viscosity greases and oil with accuracy and exactness. It is suitable for small shots and beads of high viscosity greases. It has compact size and easy to use design make dispensing efficient.

|

Seal Insertion Machine

Control your costs, part quality and production volume by automating your dispensing application. Vertex has automated the dispensing process in assemblies that benefit from receiving exacting amounts of lubricants, adhesives, sealants or mastic. Precise automated dispensing ensures both quality and quantity control. Bead size, position, and expansion area can be fully controlled and monitored. Robots are commonly used to dispense adhesives and mastics for variety of applications such as two-part mixing for fastening, panel stiffening and sound dampening. Sealants can be applied robotically to components that required a water-tight seal between two seal between two parts, or require a secondary curing process.

|

Toe Camber Machine & Checking Guage

AUTO GAUGE MACHINE FOR AXLE BEAM LINE-MANESAR

|

Shuttle Conveyor

Shuttle conveyor is a belt conveyor mounted on a travelling trolley, with travel long drive for smooth functioning to or from motion on rail. Vertex Automation provided shuttle with Hydraulic scissor lift and servo transfer. Our Engineers provide complete solution from designing to operation. We are one of the best shuttle conveyors manufacturers.

Vertex has offered shuttle conveyor to SML a 16-meter-long transfer shuttle with Hydraulic scissor lift and servo transfer for SML ROPPR.

|

Roller & Belt Conveyor

Vertexes designs unique automation conveyor system, and integrate standard conveyor system, and integrate standard conveyors to meet your automated material handling requirements. Our conveyors provide reliable presentation, automatic operation, increased quality, and increased throughput.

When designing nesting, we are able to accurately locate parts and prevent damage to critical surfaces,. CDLR/ Roller conveyors are usually powered, but also can be designed to gravity feed. Powered units can utilize slip sleeves that allow accumulation. Belt conveyors are often utilized to provide a large flat surface area to convey parts into and out automated work cells.

Project;- Vertex has offered to Trelleborg Vibracoustic , Allied

SPM Conveyor for Component Oil Dipping

|

Bending & Shearing Machine

Shearing is a process of cutting of large sheets of material into small pieces with accurate size. Bending is a process of bending plates into certain degree or creation of three dimension shapes out of two dimension stock. Vertex Automation provides different type of sharing and bending machines and customized it accounting to the customer requirement. These machines mostly used in chemical tank, safe and lockers, storage cupboard etc. We have given heat Exchanger coil bending special Purpose Machine (SPM) to Neemran.

Project;- Vertex offered to daikin (Neemrana)

HEAT EXCHANGER CUTTING AND BENDING MACHINE FOR DAIKIN INDIA

-

NEEMRANA

-

HEAT Exchanger Coil Bending SPM - NEEMRANA

|

Gantry based system

Automated Gantries are easily customizable from our templates of pre-existing designs to meet your materials.

Vertex has developed a wide range of applications in this segment. Either rack and pinion or screw- driven axes can be powered by servo or VFD motors.

Axes can also be powered pneumatically or hydraulically. Engineered end-of-arm tooling is designed to handle single or multiple parts accurately without damaging critical surfaces.

Project;- Vertex has offered to JTEKT

GANTRY & CONVEYOR SYSTEM FOR REDUCE MANPOWER

BEFORE - 15 NOS. AFTER - 03 NOS. (LOCATION : BAWAL)

|

Machine Tending

Machine Tending refers to watching over a machine while it performs a job, as well as the process of feeding parts in and out.

This is process of loading and unloading raw materials into machinery for processing.

Also known as machine loading and unloading. In this Application VERTEX offers Gripper Selection, System Design & Engineering.

|

TUBE DECOILER MACHINE

Tube Decoiler Machine developed by Team Vertex

USAGE: Decoiling/Unrolling of Tube/Cable Machine to Cutting machine

APPLICATION: Tower of Decoiler Machine senses the speed required in decoiling to maintain constant feedback of Cable/Tube to the former Cutting machine

INDUSTRY: Automotive Industry

|

CLINCHING MACHINE

Vertex Automation System Private Limited is leading manufacturer of SPM in Delhi NCR.

We have in-house manufacturing unit at Greater Noida, Surajpur Industrial Area; Vertex Automation System Private Limited manufactures SPMs for Automotive Industry & other industries like Water Treatment, Paint Shop & other industries.

|

GROMET EXPANDER MACHINE

Vertex Automation System Private Limited is leadingmanufacturer of SPM in Delhi NCR.

We have in house manufacturing unit at Greater Noida, Surajpur Industrial Area; Vertex Automation System Private Limited manufactures SPMs for Automotive Industry & other industries like Water Treatment, PAint Shop & other industries.

|

HIGH PRESSURE FLUSHING MACHINE

High Pressure Flushing Machine (HE Air Cleaning)

Vertex Team has developed High Pressure Flushing Machine for HVAC Industry to flush off any dust from component- Heat Exchanger

Vertex Automation System Pvt Ltd is a leading manufacturer of Special Purpose Machine in Delhi-NCR

Vertex Team has developed High Pressure Flushing Machine for cleaning of parts of AC.

|

AGV & ASRS

Vertex Group is currently working on Automated Guided Vehicles & Automated Storage & Retrieval System.

|

LEAKAGE TESTING MACHINE

Leak Testing Machine ensure product quality, safety and performance during Manufacturing process it also used to detect anything like pressure decay, vacuum decay, mass flow, pressure cracking, burst pressure, chamber. Vertex Group has offered this machine to Tata and KRN which is used for leakage testing in cylinder head through cosmo leak test. It detects the leakage

Project- Vertex has given this machine to Tata, KRN and many more companies

1. It is used for leakage testing in slander head through cosmo leak test

2. We have given Air leakage testing machine to Tata motor

3. Water leakage testing machine we have given to KRN

Application- Air leak testing machine

When air is charged to the work and pressure inside the work increases, the pressure difference between the inside and outside of the work will be generated.

When the work has leak by a hole, the air inside the work will flow outside and the pressure inside the work will decrease.

The change of pressure inside the work is monitored and a leak is detected through the air leak test.

|

BULB HOLDER RIVETING MACHINE

Vertex has develeped & successfully implement this project for Motherson using Hydo-pneumatic cylinders

|

SHIM BONDING & RIVETING MACHINE

Vertex offer Shim Bonding Machine which is used for four wheel brake shoe riveting with strip through rotary inducer in which component loading is manual after all operation are automatic in six rotary station with auto unloading.

Project- Vertex Automation has offered his project to Allied

Application-

1. In station, first station is use for loading

2. Second station purpose is press bond strip with pad through heating

3. Third station, is use to check all strip height and pad and observe variation in height through x-y Gantry with height checking sensor

4. Last Station is unloading station after final component is auto pick from index through magnetic gantry mechanism and they drop final component to conveyor and NG component directly in rejection bin

|

AUTO LOADER MACHINE

Vertex offer Automatic storage and racking system of M/S Allied Fabrication, so that the components can automatically loaded without any difficulty. It is used to load raw material and replace human loading efforts. Auto Loader is an automatic loading process; it can streamline and speed up the loading processes which result in more effective and fast process.

Application; -

Vertex has offered 30-meter length Conveyor line of Automatic storge and racking System of M/S Allied Fabrication to Neemrana.

AUTO GAUGE MACHINE FOR AXLE BEAM LINE-MANESAR

|

NUT RUNNER MACHINE

Nut Runner is used to tight the screw and bolts. It allow operator to evaluate torque applied to the fastener so it can meet out the specification of particular application. Vertex provide these planetary torque multiplier gearbox, has multiplication ration and Primarily is used anytime, accurate torque is required to tight nuts or when stubborn nut needs to be removed.

A nut runner has a very low Vibration level and high accuracy with excellent repeatability, which reduces human involvement and makes it perfect for bolting.

|

Welding SPM

Welding solutions can be provided from a single fixture application to a completely automated welding system. Vertex understands the necessity of robust welding tooling designs that address the harsh MIG welding environment. We have designed and built automated integrated turntables with tip dressers, check fixtures, and robots, all resulting in more profitable welding solutions. Innovative Turntable style MIG welding systems allow multiple robots to weld while an operator loads the opposite side, reducing the machine footprint and optimizing capital utilization. Quick-change turntable tooling designs provide added flexibility in low production volume situations. In this Application VERTEX Offer Welding Torch Selection, System Design & Engineering.

Projects;- Vertex offered to TPK

ROBOTIC SPOT WELDING FIXTURE FOR REAR FRAME – TPK R/L

Robot controlled

-

Voltage Parameter

-

Current Parameter

-

Wire feeding Speed

-

Welding Size.

-

Fixture movement

-

C02 GAS controlling

-

Fixture movement.

PLC Controlled

-

JIG Clamp /Declamp

-

Curtain up/down

-

Safety interlock

-

Robot Interfacing

-

HMI Interfacing & Alarm

-

Poka-yoke

|