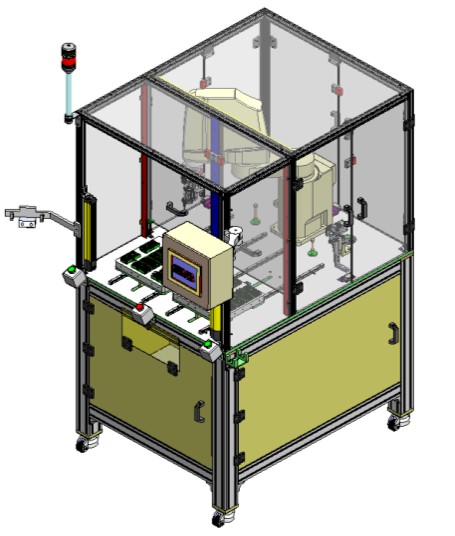

VERTEX Automation system

Vertex Automation System Pvt. Ltd. is an ISO 9001-2008 company. We provide a complete solution in the field of Industrial Automation, Turnkey projects, Robotic, Applications and Mechatronics Application with Filed experience of about 2 decades. We have successfully executed large number of applications for a wide range of industries.

ROBOTICS

Vertex Automation Provide robotic solutions from design to build by applying the leading- edge technology.

Each project is engineered to deliver the most efficient and optimal production process and incorporate state-of- the-art lean manufacturing principles. Our engineering, design, experience, creativity has result in higher profitability and efficiency. Vertex Automation offers economical robotic integration system with a multitude of flexible options. Robots reduce human efforts, increase efficiency, safety and higher volume of productivity with exacting quality control. End- of- arm- tooling is designed, engineered and assembled at vertex for our innovation robotic integration systems.

We also demonstrate and document adherence to all applicable safety standards. Automating the manufacturing processes with robotics improved the profitability by increasing the efficiency of plant.

|

Robotics Mig Welding

Robotic MIG welding can perform a variety of weld type on several different metals. The filler rod is important aspect of ARC welding.

Usually made from the same material as the base metal, it is used for reinforcing joints and welding heavy metals. ARC welding is one of several fusion processes for joining metal. Welding controller apply intense two parts so that the parts melt and intermix.

This is either done directly or more commonly with an intermediate molten filler metal. In this application vertex offer welding Torch selection, system, design & Engineering.

ROBOT CONTROLLED

-

Voltage & current Parameter

-

Wire feeding speed

-

Welding size

-

Fixture movement & gas controlling

PLC CONTROLLED

-

JIG Clamp/ De Clamp

-

Curtain up/down

-

Safety interfacing

-

Robot Interfacing

-

HMI Interfacing & Alarm

-

Poka-Yoke Confirmation

Mechanism Control

-

Lay outing

-

Designing

-

Complete prove out

-

Installing

|

SPOT Welding

Robotic SPOT welding: The process is used for joining sheet materials and uses shaped copper alloy electrodes to apply pressure and convey the electrical current through the work pieces.

In all forms of resistance welding, the parts are locally heated,the material between the electrodes yields and is squeezedtogether.

It then melts, destroying the interface between the parts. The current is switched off and the "nugget" of molten materialsolidifies forming the joint.

In this Application Vertex Offered Welding Gun Selection, System Design & Engineering.

Robot controlled

-

Current & voltage parameter.

-

Air & Water Controlling

-

SPOT Position

PLC Controlled

-

Component clamping/de-clamping

-

Spot Programmed Selection.

-

Safety interlock.

-

Robot Interfacing

-

HMI Interfacing & Alarm

-

Poka-yoke Confirmation

|

PICK-AND-PLACE

Robots can easily automate picking a part up and placing it into a desired location. Robots not only speed up the process, which increases production rates, but they are also more accurate and do not fatigue.

The consistent output of a robotic system along with quality and repeatability are unmatched. Pick and place robots can be reprogrammable and tooling can be interchanged to provide for multiple applications.

Pick and Place Robot work cells are among the most popular material handling systems. They provide dependable solutions for production lines. With this Robot performs tedious, repetitive tasks with ease, speed and accuracy.

Vertex offers PLC controller interfacing with:-

-

Conveyor

-

welding fixture

-

SSW gun,

-

De-stacking unit.

-

Tandem Press

-

Furnace unit

|

Labeling & Inspection

Labeling: Robots can be used for sticker pasting such as MRP sticker on finished goods, BE sticker, caution sticker, any kind of Logo sticker etc. For the sticker pasting application, we use feeder units to separate the sticker from its base paper & then robot picks it up & pastes it on the particular good.

Inspection: Robots can be used for Inspection application also such as leak testing, goods inspection, vision application also. We have successfully installed Robots for Labeling & Inspection application at various companies.

|

Cobot+ AGN

Cobot is a Collaborative Robot which shares a workspace with humans. These robots are different from industrial robots, Basically the are used in automobile, manufacturing, hospital etc. company tocarried-outwork like welding, spray painting etc. As we knowthere rise of collaborative robotics in SMEs and large companies and incentive spread of Automated Guided Vehicles (AGV). The combination of Cobot and AGV shows a strong synergy for the industry of the smart manufacturing.

As we all know in this changing scenario companies needs to develop a smart manufacturing unit which reduce humans’ efforts, Easier, simple and more flexible.

Features

Move easy with operating buttons; -The operating buttons on the robot arm provide you with easy control for ASSISTA and the teaching pendant for programming and teaching is no longer needed. The LED on the robot arm display the status of the robot.

No experience for robot requirement; -You can create programs visually using intuitive operations with RT-Visual-Box. "Visual Programming" - This software allows operators to simply program this robot with a "train by demonstration" programming interface. This allows them to move the robot arm position and set way-points easily.

A Wide Variety of Components and Applications; - ASSISTA offers a wide variety of components Grippers, Fingers, Vision and other peripherals developed by a group of organizations known as MELFA Robot Partners. These tools can easily be setup and configured for your application. ASSISTA can also be configured to move freely as as part of an AGV/AMR or as a mobile robot.

|

Griper with Assista

Simply Connect Grippers to Robot Arm the ASSISTA Set-up wizard provides operators with an easier more intuitive methodology for gripper configurations.

|

View with Assista

ASSISTA and the camera capture the target using the “RT VisualBox” auto-focus function.

|

Assista Moves

You can freely move ASSISTA wherever needed whenever necessary. The “AGV/AMR” unmanned transport cart secures the safety of various sensors and coexists with the operator. The company also provides a cart exclusively for use with ASSISTA, thereby enabling flexible response to changes in factory layout or the location where it is used.

|

PALLETIZATION

Palletizing refers to loading and unloading parts, boxes or other items to or from pallets. Automated palletizing refers to a Robotic palletizer performing the application automatically.

Robotic palletizing can be seen in many industries including food processing, manufacturing, and shipping.

Various end-of-arm-tooling styles allow flexibility of different types of Palletization.

In this Application VERTEX offers EOAT Selection, System Design & Engineering. By automating your shop with a palletizing system, you can increase the consistency of your loading and unloading processes.

|

DISPENSING

Dispensing jobs require materials to be moved from one location to another. The consistent, accurate movements of Robots make them well suited for dispensing. Robots provide the flexibility and reach that is often necessary when dispensing. Whether you need to lift a huge vat or dispense small objects, there's a robot model that can handle it.

Dispensing can be a hazardous, tough job too. Robots provide an opportunity to remove your workers from these repetitious jobs and transition them into safer, more rewarding work. From pouring liquids to picking and placing objects, robots are the most reliable, cost-effective dispensing solution.

In this Application VERTEX Offers EOAT Selection , System Design & Engineering.

|

DEBURRING

Robotic deburring is the material removal process used to take burrs, sharp edges, or fins off metal parts.

Manufacturers use industrial deburring robots to increase precision on the part being ground down or filed. These robots can work long hours without fatigue, increasing production.

Robotic deburring automation cells grind, roll and file metal parts with precision, improving the quality of the product. Robotics are more affordable today.

Many factories are looking to buy a robotic deburring cell for their operation. With expert engineering, a deburring application can bring your company a positive return on investment

|

PRESS TENDING

Press Tending used to be a tedious, dangerous task. Loading and unloading parts from a press, operating the machine, and maintaining consistency with every part proved tedious work. Now the entire scenario has been changed with the introduction of robots in this field. They have taken over the job of precisely placing blanks into press machines each and every time. They are faster, more productive, and error proof.

Robot press tending goes beyond simply moving parts in and out of machines. Robots can move parts around to three or four dies within the same press.

Robots are also useful in rotating, flipping, tilting a part between press operations. These are highly productive in compound die presses.

|